CRSI: CRSI Home Page

Design and Detailing of LowRise Reinforced Concrete Buildings. Reinforcing Bars: Anchorages and Splices. Concrete Structures Reduce the Spread of Fire The Mercer

WhatsApp)

WhatsApp)

Design and Detailing of LowRise Reinforced Concrete Buildings. Reinforcing Bars: Anchorages and Splices. Concrete Structures Reduce the Spread of Fire The Mercer

Aug 26, 2014· Professor, Department of Mechanical Engineering, Knowledge Institute Of Technology, Tamil Nadu, India Abstract The present work aims to design and analysis of Ball mill inlet chute along with the truck assembly for Roller press circuit UMS (Unidan Mill S) type FLS Ball mill which are used in the Cement industry for grinding clinker material.

The mill reports certify that the reinforcing bar conforms to the project specifications and reveals the chemical composition of the reinforcing bar and mechanical properties. Reinforcing bars typically come in two primary grades: Grade 60, which has a minimum yield strength of 60,000 psi, and Grade 75, which has a yield strength of 75,000 psi.

A trusted resource since 1986, PENTA has provided services to numerous cement plants in virtually every region of the world. Our indepth knowledge and comprehensive services combined with the extensive experience of our staff allows us to completely develop projects from conceptual design to .

design criteria in AWWA C110/111, ANSI / for tolerances, dimensions and configuration of the time proven mechanical joint seal. Custom Built For Specific Application this versatile mechanical joint fitting is built to meet the specific requirements of special applications. Eliminates lost time due to field or factory modifications.

Dec 18, 2012· 150, 12″ Swing, Metal Lathe, Mill, and Drill . Almostfree metal lathe, drill and milling machines. Accurate and scalable to any size. Technology used has been proven for almost 100 years. Easily made from scrap, steel bar and concrete. Built with common hand tools, a .

the home of International Cement Review, the world''s most requested magazine in the global cement industry. Leaders in News, Conferences, Training and Reports

criterion. For each cement type a PID set is selected and put in operation in a closed circuit cement mill. The performance of the regulation is evaluated after a sufficient time period, concluding that the developed design combining criteria of both robustness and .

The Mechanical Concrete® bottom line is a quantum leap forward in strength, scalability, and economy for confinement technology. It reuses a major societal waste product—the used auto tire—so Mechanical Concrete® is bright green and economic. Now, that''s real 21 st century sustainability.

Ball mill Wikipedia. The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals.

Mechanical Behavior of White Concrete. Hüseyin Temiz. 1, M. Metin Kose1, ... Mix design of the concrete mixtures with the maximum aggregate size of 16 and 32 mm were determined according TS 802 and given in Table 3 ... concrete was determined by testing of three samples.

The ball mill is a key piece of equipment for grinding crushed materials, and it is widely used in production lines for powders such as cement, silicates, refractory material, fertilizer, glass ceramics, etc. as well as for ore dressing of both ferrous and nonferrous metals. The ball mill can grind various ores and other materials either wet or dry.

Cement manufacturing: components of a cement plant. This page and the linked pages below summarize the cement manufacturing process from the perspective of the individual components of a cement plant the kiln, the cement mill etc.. For information on materials, including reactions in the kiln, see the '' Clinker '' pages.

The Bashundhara Group has started operation as a real estate venture known as "Bashundhara" under the aegis of the Group''s first concern – the East West Property Development (Pvt) Ltd in 1987. This project turned out to be a very successful one and had helped foster the growth of trust and confidence of the urban people in "Bashundhara".

cement mills manufacturescement mills mechanical . cement mills mechanical design pdf grinding mill equipment. cement mills mechanical design pdf Cement Mill Mechanical Books india addition to Cement Mill Mechanical Books we also sell ball mills pdf cnc milling More info Cement ore crusher price A cement is a binder a substance used for construction that sets hardens and adheres to other ...

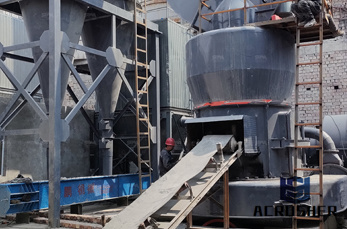

A cement mill (or finish mill in North American usage) is the equipment used to grind the hard, nodular clinker from the cement kiln into the fine grey powder that is cement is currently ground in ball mills and also vertical roller mills which are more effective than ball mills.

Portland Cement Manufacturing Process Description17 Portland cement is a fine powder, gray or white in color, that consists of a mixture of hydraulic cement materials comprising primarily calcium silicates, aluminates and aluminoferrites. More than 30 raw materials are known to be used in the manufacture of portland cement, and these

The files below contain TxDOTapproved products and materials from various manufacturers and producers. Each file may contain the following information:

Certified mill test reports typically accompany each shipment of reinforcing bars. The mill reports certify that the reinforcing bar conforms to the project specifications and reveals the chemical composition of the reinforcing bar and mechanical properties.

The SIRI CONSULTANTS (SIRI) is Hyderabad based Industrial Consultants headed by Rao, –Structures, IIT Chennai (GOLD MEDALIST) specialized in Architectural, Civil, Structural, Mechanical and Material Handling projects having executed around .

By this summer, a grinding mill that is bigger around than a Boeing 747 will turn chunks of copper ore into gravelsized bits for smelting and refining. The largest ring gear will make it happen

Metallurgical ContentBall Mill Maintenance ManualOn Mill Installation and MaintenanceBall Mill Concrete FoundationsGrinding Mill FOUNDATIONGROUTINGBall Mill Sole Plate Am sure your Ball Mill is considered the finest possible grinding mill available. As such you will find it is designed and constructed according to heavy duty specifications.

Volume 3, Issue 5, November 2013 385 Abstract— formalized by French and British engineers in the 18th This paper analyzes an existing processing management system in a cement factory in India. During the last two decades (80''s and 90''s), major technological advancements took place in design of cement plant equipment/systems. The

For heavy milling, such as bit cones, slips, and pieces of downhole tools, conebuster mills have a concave cutting face with a thick cutting structure. This structure ensures efficient milling and long life. Conebuster mills are available from 3 1/2 to 17 1/2 in, with fishing necks from 3 1/8 to 9 1/2 in. Cement mills

WhatsApp)

WhatsApp)